The Use of Laboratory Asphalt Devices: A Comprehensive Guide

2024-06-25 16:35:16

I. Introduction

In modern transportation construction and waterproofing projects, asphalt, as a key material, its performance is directly related to the quality and durability of the project. To ensure that the quality of asphalt materials meets the standards, laboratory asphalt devices have become indispensable tools. These devices are not only used in scientific research and teaching but also play a crucial role on the production line. This article aims to provide readers with a comprehensive guide to the use of laboratory asphalt devices to help everyone better master their operation methods and precautions.

II. Overview of Laboratory Asphalt Devices

Laboratory asphalt devices, as the name suggests, are a collection of equipment specifically used for detecting and analyzing the performance of asphalt materials. They include but are not limited to softening point testers, penetration testers, ductility testing machines, etc. Each device has its specific test items and functions, jointly constituting a complete system for evaluating the performance of asphalt materials. The importance of these devices is self-evident. They provide accurate data support for researchers and standard basis for quality control for production personnel.

III. Basic Operations of Laboratory Asphalt Devices

Equipment Preparation

Before using laboratory asphalt devices, a comprehensive inspection of the equipment is required first. Confirm whether the device is intact and whether the required accessories are complete. At the same time, preheat the equipment to the specified temperature according to the test requirements to ensure a stable test environment. This step is the basis for ensuring the accuracy of the test results.

Before using laboratory asphalt devices, a comprehensive inspection of the equipment is required first. Confirm whether the device is intact and whether the required accessories are complete. At the same time, preheat the equipment to the specified temperature according to the test requirements to ensure a stable test environment. This step is the basis for ensuring the accuracy of the test results.

Sample Preparation

The preparation of asphalt samples is an important link in the testing process. It is necessary to collect and process asphalt samples strictly in accordance with relevant standards to avoid the influence of pollution and temperature fluctuations on the performance of the samples. During the preparation process, attention should be paid to maintaining the uniformity and representativeness of the samples to ensure the reliability of the test results.

The preparation of asphalt samples is an important link in the testing process. It is necessary to collect and process asphalt samples strictly in accordance with relevant standards to avoid the influence of pollution and temperature fluctuations on the performance of the samples. During the preparation process, attention should be paid to maintaining the uniformity and representativeness of the samples to ensure the reliability of the test results.

Testing Operations

Testing operations are the core link in the use of laboratory asphalt devices. According to different test items, select the appropriate device and conduct the test in accordance with the operating procedures. For example, in the softening point determination, the asphalt sample needs to be placed in the softening point tester, set the heating rate and temperature range, and then observe and record the temperature at which the asphalt begins to soften. In the penetration test, the standard needle needs to be perpendicularly inserted into the asphalt sample to measure the penetration depth to evaluate the consistency of the asphalt. In the ductility test, the asphalt sample is stretched to the breaking point, and the elongation length is measured to evaluate its flexibility.

Testing operations are the core link in the use of laboratory asphalt devices. According to different test items, select the appropriate device and conduct the test in accordance with the operating procedures. For example, in the softening point determination, the asphalt sample needs to be placed in the softening point tester, set the heating rate and temperature range, and then observe and record the temperature at which the asphalt begins to soften. In the penetration test, the standard needle needs to be perpendicularly inserted into the asphalt sample to measure the penetration depth to evaluate the consistency of the asphalt. In the ductility test, the asphalt sample is stretched to the breaking point, and the elongation length is measured to evaluate its flexibility.

Data Processing and Analysis

After the test is completed, the collected data needs to be processed and analyzed. This includes steps such as data cleaning and statistical analysis. By comparing and analyzing the test results under different conditions, the performance changes of the asphalt material and their causes can be evaluated. At the same time, improvement suggestions can also be proposed based on the test results to provide a scientific basis for material research and development and production.

After the test is completed, the collected data needs to be processed and analyzed. This includes steps such as data cleaning and statistical analysis. By comparing and analyzing the test results under different conditions, the performance changes of the asphalt material and their causes can be evaluated. At the same time, improvement suggestions can also be proposed based on the test results to provide a scientific basis for material research and development and production.

IV. Maintenance and Upkeep of Laboratory Asphalt Devices

To maintain the good performance and extend the service life of laboratory asphalt devices, regular maintenance and upkeep are required. This includes cleaning the equipment, checking the wear of components, and regular calibration. During use, attention should also be paid to avoiding behaviors that may cause equipment damage, such as severe vibration and impact. In addition, devices with faults should be troubleshot and repaired in a timely manner to ensure their normal operation.

V. Safety Precautions

When using laboratory asphalt devices, safety regulations must be strictly followed. Since asphalt materials are prone to volatile toxic gases and are flammable and explosive at high temperatures, attention should be paid to ventilation and staying away from fire sources during use. At the same time, protective equipment such as gloves and masks should be worn during the operation to prevent accidents such as burns and poisoning. In addition, an emergency plan should be formulated to deal with possible emergencies such as fires.

VI. Sharing of Practical Cases

A certain scientific research institution used laboratory asphalt devices for performance testing when developing new asphalt materials. Through the comprehensive application of devices such as softening point testers, penetration testers, and ductility testing machines, they successfully evaluated the performance of the new materials and discovered the existing problems. According to the test results, they promptly adjusted the material ratio and process parameters and finally successfully developed a new type of asphalt material with excellent performance. This case fully demonstrates the important role and value of laboratory asphalt devices in material research and development.

VII. Development Trends of Laboratory Asphalt Devices

With the continuous development and progress of science and technology, laboratory asphalt devices are also constantly innovating and improving. In the future, we can foresee that intelligence, automation, and greening will become the main trends in the development of laboratory asphalt devices. Intelligent technology will enable devices to have a higher degree of automation and more powerful data processing capabilities; automation technology will reduce errors caused by manual operations and improve test efficiency and accuracy; while green technology will promote the research and development and application of environmentally friendly asphalt devices and contribute to sustainable development.

VIII. Conclusion

In conclusion, as an important tool in the field of materials science, laboratory asphalt devices, and their usage methods and precautions are of great significance for ensuring the accuracy and reliability of test results. Through the introduction in this article, we hope to help readers better master the usage skills of laboratory asphalt devices and provide strong support for their application in scientific research, teaching, and production practice. At the same time, we also look forward to the continuous development of science and technology, and laboratory asphalt devices can play a greater role in more fields and make greater contributions to promoting the development of transportation construction and waterproofing projects.

Digital concrete penetration apparatus

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

V-Funnel apparatus

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

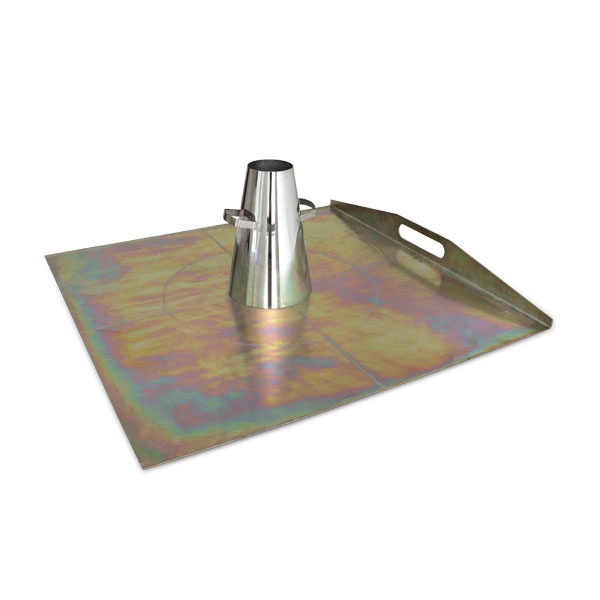

Slump-flow test apparatus

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

Sieve segregation test set

Used for determining the sieve segregation resistance of self-compacting concrete. This met...