Concrete Pan Mixer: The Key Driving Force for Enhancing Mixing Efficiency and Quality

2024-07-09 19:29:04

In the fast-growing construction industry nowadays, concrete, as the cornerstone of infrastructure such as high-rise buildings, bridges, and roads, its quality and performance directly determine the stability and durability of engineering projects. Behind this, the concrete pan mixer, with its unique advantages, has become the key equipment for improving the efficiency and quality of mixing. This article will deeply explore the role of the concrete pan mixer and reveal its significance in modern construction.

I. The Rising Background of Concrete Pan Mixers

With the vigorous development of the construction industry, the demand for concrete is increasing day by day, and the requirements for concrete mixing equipment are also getting higher. Although traditional mixers can meet the basic mixing needs, they often have deficiencies in efficiency and quality. However, the concrete pan mixer has rapidly emerged in the construction industry with its innovative mixing principle and efficient mixing performance.

II. The Basic Structure and Working Principle of Concrete Pan Mixers

The concrete pan mixer adopts an advanced mixing pan design. Through the rotation and tilting movement of the mixing pan, the raw materials are fully mixed in the mixing chamber. Its unique mixing path and efficient mixing mechanism ensure the uniformity and stability of the concrete. At the same time, the precise coordination of the drive device and the transmission system makes the mixing process more stable and reliable.

III. The Main Functions of Concrete Pan Mixers

Improving Mixing Efficiency: The concrete pan mixer significantly shortens the mixing time and enhances the mixing efficiency by optimizing the mixing path and increasing the mixing speed. This not only speeds up the construction progress but also reduces the production cost.

Ensuring Concrete Quality: During the mixing process, the concrete pan mixer can ensure the full mixing of raw materials, reduce air bubbles and unmixed materials in the concrete, thereby improving the strength and durability of the concrete. This is of great significance for ensuring the quality of the project.

Adapting to Various Mixing Demands: The concrete pan mixer has flexible adjustment functions and can adjust the rotation speed and tilting angle of the mixing pan according to different concrete formulations and mixing needs. This enables it to handle various types of concrete mixing with ease.

Energy Saving and Environmental Protection: Compared with traditional mixers, the concrete pan mixer can reduce energy loss and noise pollution during the mixing process, which is in line with the green development concept of the modern construction industry.

IV. Application Examples of Concrete Pan Mixers

From high-rise buildings to bridges and tunnels, from urban roads to water conservancy facilities, concrete pan mixers are widely used in various large-scale construction projects. It not only improves the mixing efficiency and quality but also provides a strong guarantee for the smooth progress of the project. At the same time, in the ready-mixed concrete production line, the concrete pan mixer has become one of the indispensable core equipment.

V. Maintenance and Upkeep of Concrete Pan Mixers

To ensure the long-term stable operation and prolong the service life of the concrete pan mixer, regular maintenance and upkeep are crucial. This includes daily cleaning, lubrication, fastening, and inspection. At the same time, common faults and problems that occur also need to be diagnosed and eliminated in a timely manner. Only in this way can it be ensured that the concrete pan mixer always maintains a good working condition and performance.

VI. Looking Forward to the Future: The Development Trend of Concrete Pan Mixers

With the continuous development of the construction industry and technological progress, the concrete pan mixer will also have a broader development prospect. In the future, we can expect greater breakthroughs in intelligence, automation, energy saving, and environmental protection of concrete pan mixers. At the same time, with the continuous emergence and application of new materials and new technologies, the performance of concrete pan mixers will also be further improved and perfected.

In conclusion, as one of the indispensable key equipment in the modern construction industry, the role of the concrete pan mixer in improving the mixing efficiency and quality cannot be underestimated. In the future, with the continuous progress of technology and the continuous expansion of application scenarios, the concrete pan mixer will surely contribute more to the sustainable development of the construction industry.

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

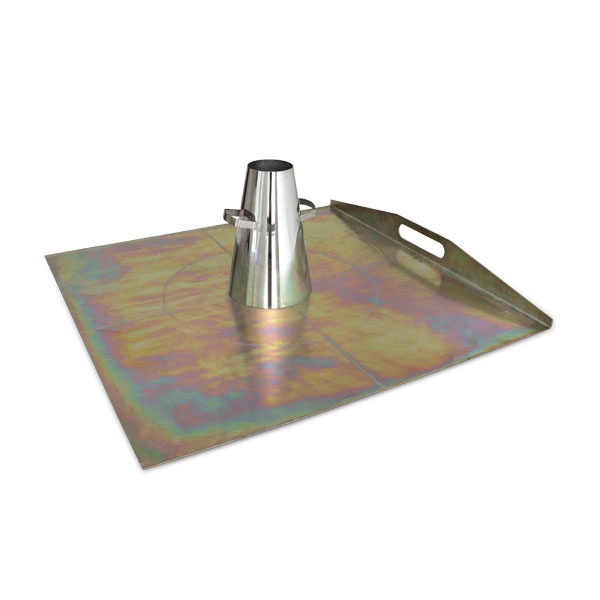

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

Used for determining the sieve segregation resistance of self-compacting concrete. This met...