In-depth Analysis of the Characteristics of Mortar Testing Devices and Their Importance in Engineering Quality Control

2024-06-20 16:13:39

I. Introduction

In the vast field of construction engineering, mortar, as the cornerstone for connecting bricks and stones and building strength, its stable and superior performance is directly related to the safety and durability of the entire project. To ensure that the quality of mortar meets the design requirements, an efficient and accurate mortar testing device has become an indispensable tool. This article will deeply analyze the characteristics of these testing devices and explore their key role in engineering quality control.

II. Overview of Mortar Testing Devices

Mortar testing devices, as the name suggests, are a collection of equipment specifically used to detect various performance indicators of mortar. They accurately measure key parameters such as the strength, fluidity, and setting time of mortar by simulating various conditions in the actual working environment. According to different testing purposes and structural forms, these devices can be divided into multiple types such as compressive strength testing machines, flexural strength testing machines, and fluidity testers, and are widely used in multiple links such as the research and development, production, construction, and quality inspection of building materials.

III. Core Characteristics of Mortar Testing Devices

High-precision Measurement Capability: Modern mortar testing devices are generally equipped with high-precision sensors and data acquisition systems, which can achieve accurate capture and recording of test results. This high precision not only ensures the accuracy of the test data but also improves the repeatability of the test results, providing solid data support for engineering quality control.

Multifunctionality and Flexibility: To meet the testing requirements of different types and specifications of mortar, testing devices often have multifunctionality and flexibility. By adjusting test parameters or configuring different accessories, these devices can easily cope with various testing scenarios, providing great convenience for researchers and production personnel.

Automation and Intelligence: With the advancement of technology, more and more mortar testing devices are integrating automation and intelligent technologies. The automated control system can reduce errors caused by human operations and improve testing efficiency; while the intelligent analysis software can quickly process test data and generate detailed test reports, providing a more scientific basis for decision-making.

Durability and Stability: As long-term used testing equipment, the durability and stability of mortar testing devices are crucial. The selection of high-quality materials and reasonable structural design ensure that these devices can maintain stable performance in harsh working environments and extend their service life.

Safety Performance: Safety is always an important consideration in equipment design. Mortar testing devices are equipped with multiple safety protection measures, such as overload protection and emergency stop buttons, to ensure the safety of personnel and equipment during the testing process.

IV. Sharing of Practical Cases

Taking a large-scale construction project as an example, the project conducted a comprehensive performance test on the mortar used before construction. By using advanced testing devices, the project team successfully detected the key parameters such as the strength and fluidity of the mortar and optimized the material ratio based on the test results. This not only improved the performance indicators of the mortar but also ensured the quality and safety of the entire project.

V. Development Trends of Mortar Testing Devices

Looking forward to the future, mortar testing devices will develop in a more intelligent and green direction. On the one hand, with the continuous progress of artificial intelligence technology, testing devices will have more autonomous learning and decision-making capabilities, and be able to automatically adjust test parameters and optimize test processes; on the other hand, the research and development of environmentally friendly testing devices will also become an important trend in the industry, promoting the sustainable development of the construction industry through energy conservation, consumption reduction, and reduction of waste emissions.

VI. Conclusion

In conclusion, as an important tool for engineering quality control, mortar testing devices, with their characteristics such as high precision, multifunctionality, automation, and intelligence, provide strong support for the development of the construction industry. With the continuous progress of technology and changes in the market, we have reasons to believe that these testing devices will play a more important role in the future and promote the continuous improvement of the quality and safety level of construction projects.

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

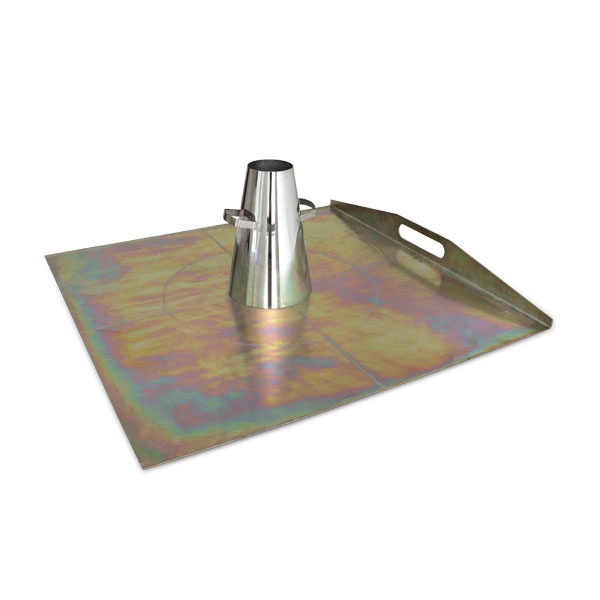

Used for determining the sieve segregation resistance of self-compacting concrete. This met...