Detailed Instructions for the Use of Laboratory Asphalt Mixers: The Key to Enhancing Experimental Efficiency and Data Accuracy

2024-06-30 10:07:30

In the fields of materials science and road engineering, the application of laboratory asphalt mixers plays a vital role. It is not only the core equipment for the research and development of asphalt mixtures but also a crucial tool for ensuring the accuracy of experimental data and promoting technological progress. This article will elaborate on the usage methods of laboratory asphalt mixers, aiming to assist researchers in better grasping operational skills and improving experimental efficiency and data accuracy.

I. Understanding the Importance of Laboratory Asphalt Mixers

The laboratory asphalt mixer uniformly blends asphalt and aggregates by precisely controlling the mixing temperature, time, and speed to form asphalt mixtures that meet specific requirements. This process is crucial for evaluating the physical properties, chemical stability, and durability of asphalt mixtures. Therefore, mastering the usage methods of asphalt mixers is the basis for researchers to conduct high-quality research.

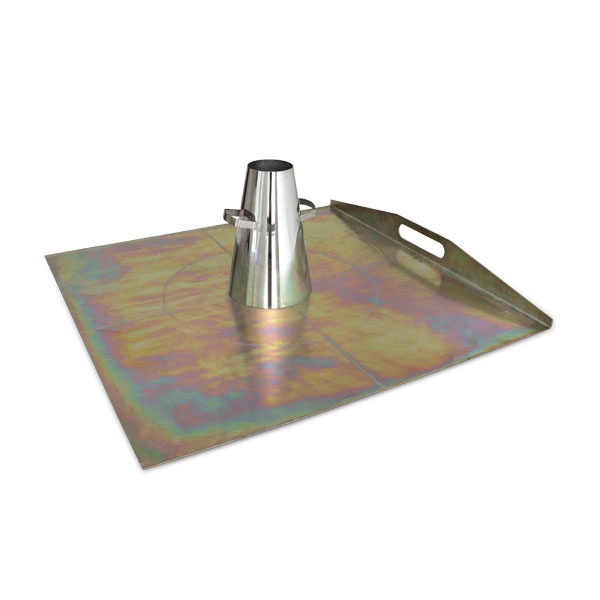

II. In-depth Understanding of Equipment Structure and Characteristics

Laboratory asphalt mixers typically consist of key components such as a mixing pot, heating system, mixing paddle, and control system. Different models of equipment vary in aspects such as capacity size, adjustment range of mixing speed, and temperature control accuracy to meet different experimental needs. When selecting and using, it is necessary to choose the appropriate model based on the specific requirements of the experiment to ensure the smooth progress of the experiment.

III. Careful Preparation for Ensuring Experimental Success

Before using the asphalt mixer, thorough preparation is of utmost importance. Firstly, conduct a safety inspection to ensure that all components of the equipment are intact, the power connection is correct, and the safety protection devices are effective. Secondly, prepare the necessary materials for the experiment, such as asphalt, aggregates, and additives, and ensure that the materials are dry and free of impurities. Simultaneously, start the heating system in advance according to the experimental requirements to preheat the mixing pot to reach the preset temperature and maintain stability.

IV. Standardized Operations for Improving Experimental Quality

During the operation process, it is necessary to strictly follow the regulations. Firstly, add asphalt and aggregates to the mixing pot in sequence according to the experimental ratio, taking care to avoid material splashing. Subsequently, set parameters such as mixing time and mixing speed through the control system to ensure they meet the experimental requirements. After starting the mixer, closely observe the mixing situation and adjust the mixing parameters if necessary to ensure uniform mixing. After the mixing is completed, promptly take samples for performance testing to evaluate various performance indicators of the asphalt mixture.

V. Focusing on Details to Ensure Experimental Safety

During the experiment, special attention should be paid to personal protection and equipment safety. Wear protective equipment such as safety glasses and gloves to prevent injuries from high-temperature asphalt or flying debris. At the same time, pay attention to observing the operating status of the equipment and stop it immediately for inspection if any abnormalities are found. Additionally, conduct regular maintenance of the equipment, such as cleaning the residues on the mixing pot and mixing paddle, inspecting the power lines and safety protection devices, etc., to ensure stable equipment performance and prolong its service life.

VI. Conclusion

The correct usage methods of laboratory asphalt mixers are of great significance for improving experimental efficiency and data accuracy. By mastering the equipment structure and characteristics, preparing well before the experiment, standardizing the operation process, focusing on details and safety guarantees, researchers can conduct the research and development of asphalt mixtures more efficiently and contribute to the technological progress in the field of road engineering. At the same time, this article also reminds the majority of researchers to pay attention to the importance of equipment maintenance and upkeep to ensure the long-term stable operation of experimental equipment and the reliability of experimental data.

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

Used for determining the sieve segregation resistance of self-compacting concrete. This met...