Maintenance and upkeep of cement standard curing box

2024-04-02 00:25:05

Maintenance and upkeep of cement standard curing box:

1. If the fluctuation of the power supply exceeds the specified range of use, a power stabilizer needs to be installed, otherwise it will damage the instrument and refrigeration unit.

2. The grounding of the power supply must be excellent, as poor grounding can pose a danger to your personal safety.

3. Regularly check the humidifier, do not cut off water in the dry and wet box, and replace the gauze inside the box every month.

4. Non relevant personnel are not allowed to change the control program data without authorization to avoid causing the instrument to lose control and damage.

Troubleshooting of cement standard curing box:

1. The whole machine is not working. Check if the power switch and fuse are damaged.

2. If not cooling, check if the instrument shows cooling status, check if the compressor overload protector and starter are damaged. If the compressor can operate normally but not cooling, it may be due to refrigerant leakage.

3. The humidifier is not humidified. Check whether the small fan inside the humidifier is working, whether the water level in the humidifier base is too high, whether the humidifier is tilted too much when placed, and whether the atomization transducer is clean.

4. Occasionally, due to external telecommunications signals, the instrument panel may lose control of its digital display. Simply turn off the switch or unplug the power plug, and then restart to ensure normal operation.

Debugging and installation of cement standard curing box;

1. The instrument should be placed in a ventilated and dry place, with an ambient temperature of 238 ° C and a relative humidity of not less than 85%. It should be used indoors under the influence of strong vibrations and strong electromagnetic fields,

2. After the instrument is placed stably, it should be checked whether the box door switch is flexible and whether the electrical, refrigeration and other components are damaged.

3. Open the side door and fill the humidification water tank with distilled or purified water. Also, fill the plastic water tank at the temperature sensor with water and soak the gauze in water.

4. Insert the power plug into a 220V socket with good grounding, turn on the power switch, and the instrument will automatically enter the working state.

5. When leaving the factory, this instrument is programmed into a standard setting program, with a temperature control value of 20 ° C ± 1 and a humidity control value of 65% ± 2%. If it is necessary to change the control value data, the parameters can be modified according to the temperature controller manual.

Cement standard curing box testing machine:

Whether the refrigerator and humidifier can work depends on manually heating the head of the dry and wet sensor to a temperature higher than the set temperature of 510 ° C, which can increase the temperature difference between dry and wet, and the refrigerator and humidifier will start working immediately.

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

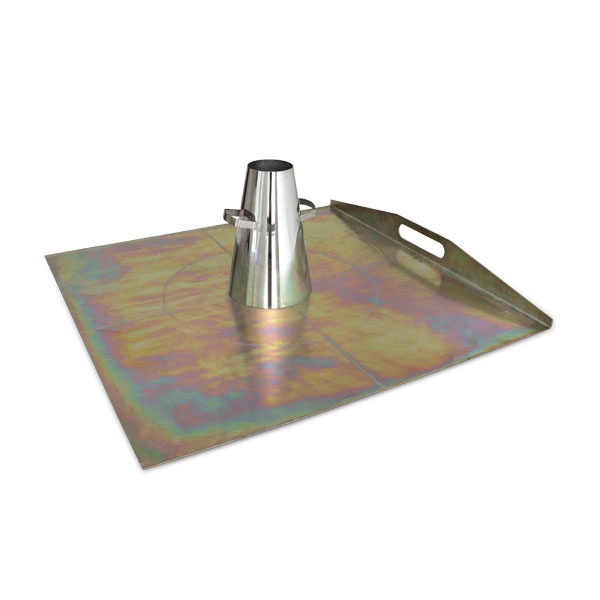

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

Used for determining the sieve segregation resistance of self-compacting concrete. This met...