Daily maintenance work of pressure testing machines

2024-04-02 00:23:24

Daily maintenance work of pressure testing machine:

1. Check the sound of the cylinder and moving parts at all levels, listen carefully, and distinguish whether they are working normally. If any abnormal sound is found, stop the machine immediately for inspection;

2. Pay attention to whether the indicated values of pressure gauges at all levels, pressure gauges on air storage tanks and coolers, and lubricating oil pressure gauges are within the specified range;

3. The pressure testing machine should regularly check whether the cooling water temperature and flow rate are normal;

4. Check the supply of lubricating oil and the lubrication system supply of the motion mechanism; The cylinder and packing can be checked for oil discharge using a one-way valve, which can check the oil injection into the cylinder by the oil injector;

5. Observe whether the oil level in the oil pool of the machine body and the lubricating oil in the oil injector are below the scale line. If they are low, they should be added in a timely manner;

6. Check the temperature of the suction and exhaust valve covers at the cross guide rail of the crankcase of the machine body;

7. Pay attention to the temperature rise of the motor, bearing temperature, and whether the readings on the voltmeter and ammeter of the pressure testing machine are normal. The current should not exceed the rated current of the motor. If it exceeds the rated current, stop the machine for inspection and identify the cause;

8. Regularly inspect the motor for debris or even conductive objects, damage to the coils, and friction between the stator and rotor. Otherwise, starting the motor may cause it to burn out;

9. Regularly check whether the pressure testing machine vibrates and whether the foundation screws are loose or detached;

10. Regularly check whether the pressure regulator or load regulator is sensitive;

11. Regularly pay attention to the hygiene of the compressor, associated equipment, and environment;

12. Air storage tanks, coolers, and oil-water separators should frequently discharge oil and water;

13. The lubricating machine used should be precipitated and filtered. Winter and summer compressor oil should be used differently;

The digital concrete penetration apparatus apparatus is used to determine the setting time ...

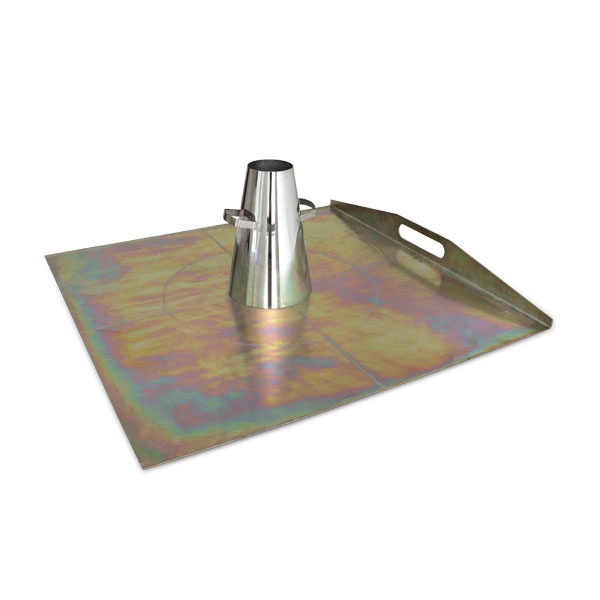

This apparatus is used to evaluate the segregation resistance of freshly mixed self-compact...

This test method covers evaluation of the deformability of freshly mixed self-compacting co...

Used for determining the sieve segregation resistance of self-compacting concrete. This met...